The Overview of Parboiled Rice and Production Process

1. Overview of Parboiled Paddy Rice

1.1 What is parboiled paddy rice

Parboiled rice is the third type of rice recognized by the Food and Agriculture Organization of the United Nations (according to the processing technology). It uses rice as the raw material. It is first subjected to strict cleaning and classification. Natural healthy rice is produced by thermal processing and short-term high-pressure steam, and then dehulling and milling.

According to authoritative testing, the content of B vitamins, dietary fiber, and various minerals in parboiled rice is 2-4 times that of ordinary polished rice. The comprehensive nutrition retention rate of rice is as high as 80%, which is far greater than that of polished rice and only 5%. The nutrition of the rice is retained.

1.2 Advantages of Parboiled Rice

(1)High nutritional value

After the rice is hydrothermally treated, water-soluble nutrients such as vitamins and inorganic salts in the cortex diffuse into the endosperm, increasing the nutritional value of parboiled rice.

(2)High meal rate

In the case of the same degree of dryness of the rice, the rice output rate is 37-76% higher than that of white rice of the same quality.

(3)Short cooking time

Easy to cook and can save fuel.

(4)Shelf-stable

After the rice is cooked, most of the microorganisms are killed, reducing pest erosion; the rice enzyme is inactivated, the germination ability is lost, and the storage period is prolonged. The characteristic of parboiled rice is extremely suitable for food transportation and storage under special environments and conditions.

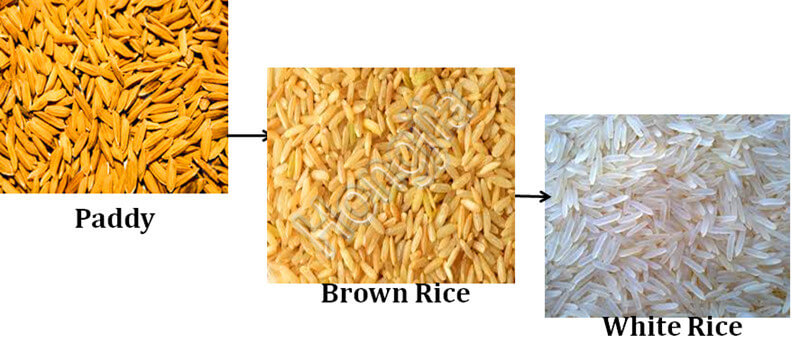

1.3 What is the difference between brown rice, white rice, and parboiled rice?

(1)Brown rice, brown rice is the caryopsis after the outer protective skin of rice is removed. Compared with white rice, brown rice contains more vitamins, minerals, and dietary fiber. However, because of the more crude fiber in the inner protective cortex, sugar wax, etc., the taste is better. Coarse, tight in texture, and time-consuming to cook.

(2)White rice, white rice has a delicate taste and is easy to digest, but the nutrient-rich part of the outer layer of the rice after grinding is lost, and the preservation rate of vitamins and minerals is less than 30%. In terms of cooking, rice is easier to steam but has a high glycemic index.

(3)Parboiled rice, commonly known as "semi-boiled rice" in the international market, is rice products, vitamins, and minerals produced by conventional rice milling methods after washing, soaking, cooking, drying, and other hydrothermal treatments using rice as raw material. The material preservation rate is high, at the same time it is easier to cook, and the cooking time is short.

1.4 Current status and prospects of parboiled rice

(1)Parboiled rice is not widely known in China, but it is very popular in Europe, America, the Middle East, and other regions. It is famous for healthy rice and green food abroad. 1/5 of the rice in the world is processed into parboiled rice every year, in India, Thailand, Africa, etc. The country is the main producer of parboiled rice. The United States, Italy, and other countries also produce it, mainly to improve the nutritional value and processing quality of rice. The selling price of parboiled rice in the international market is usually 5% to 10% higher than that of white rice of the same specification, and the benefits are significant. Due to high processing costs, darker beige, poor stickiness of rice, and taste habits, it has not been generally accepted by domestic consumers.

(2)Parboiled rice can stimulate the core rare nutrients such as γ-aminobutyric acid in the rice germ so that it has the triple balanced original nutrition of "rice skin nutrition + rice embryo nutrition + rice grain nutrition". The glycemic index (GI) of 45.76% is far lower than the international standard for low-GI foods, and long-term consumption is more conducive to the continued stability of human blood sugar levels. As Chinese people pay more and more attention to healthy eating, parboiled rice has begun to be sold in supermarkets and online in some developed areas of the country. The selling price is generally higher than the normal price of polished rice.

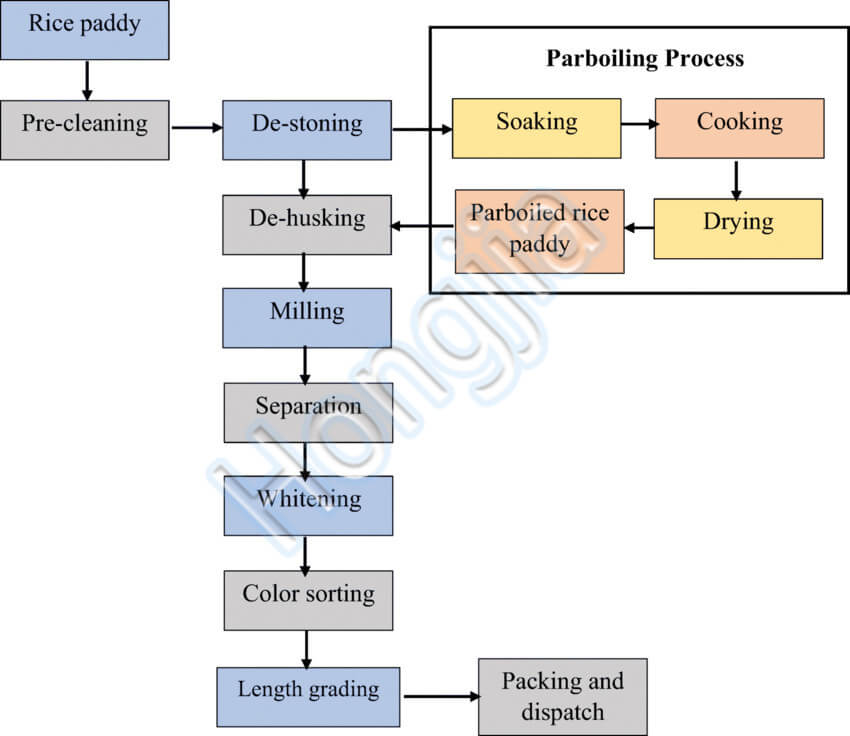

2. Production process of parboiled rice

The production process of parboiled rice is to use rice as the raw material. It first undergoes strict cleaning and grading. The rice husks are treated by a series of hydrothermal processes such as soaking, cooking, drying, slow cooling, and short-term high-pressure steam. Natural healthy rice is made from rice with shell and color selection.

Soaking: the high-temperature soaking method of vacuum, constant temperature, and pressure is used to make the rice reach the specified ratio

Cooking: The tank body of the cooking equipment is made of food and 304 stainless steel, and the temperature, time, and uniformity of the steam are strictly controlled

Drying: Use the heat of the boiler to convert it into hot air to indirectly dry the rice, reduce the rate of the bursting of the waist, and increase the rate of whole rice

Slow Su/Cooling: The rice is sent to the vertical silo for slow cooling, which takes out the remaining heat and makes the rice moisture evenly.

3. The characteristics of parboiled rice drying

3.1 The characteristics of parboiled rice drying

(1)The steamed rice is soft

(2)Most outdoor use

(3)Poor liquidity

(4)High moisture

After field investigation and research, parboiled rice has the characteristics of high water content, poor grain fluidity, and softer and springy rice grains after cooking. Because of the above characteristics, combined with the shortcomings of drying parboiled rice in domestic and foreign dryers, our company conducts Technological improvements and technological breakthroughs

3.2 The shortage of parboiled rice dryers abroad

(1)Security is not high

The hoist generally has no tic-tac-toe frame, no guardrail on the top, etc., and the safety of installation and maintenance is low, and the stability of the equipment is low.

(2)Low degree of automation

The equipment is generally controlled by the button of the control box, and the operation of the equipment is controlled by the button switch

(3)Inaccurate moisture

Generally, no moisture meter is equipped, and the user's experience is used to judge whether the moisture point for storage or reprocessing is reached

(4)Insufficient material and workmanship

Many are workshop-style production, low-end products are made of galvanized sheet and carbon steel

3.3 The shortcomings of low-temperature circulating drying parboiled rice in my country

(1)Low-temperature cyclic drying, slow drying speed, and high cost, far below the process requirements for drying parboiled rice

(2)The grain fluidity of parboiled rice is poor, and the low-temperature circulating dryer is easy to bridge and block the grain, which affects the user's use

(3)The low-temperature circulating dryer needs to be used indoors, and the user's installation cost is high

(4)Low-temperature circulation dryer screw auger conveying, parboiled rice has a high crushing rate and deformation rate

3.4 Our solution

(1)The drying cabinet and the drying part are made of stainless steel, and the hoist is equipped with tic-tac-toe and guardrails, ensuring safety for outdoor use

(2)Cancel the upper and lower augers, calculate the inclination angle of the flow tube through scientific and rigorous calculations, increase the grain fluidity and reduce the crushing rate

(3)Japanese technology fully automatic high-precision moisture meter, introduces 5G interconnection technology, data storage, and analysis, and realizes intelligent drying

(4)Scientific drying and slow-down, speeding up the drying speed and saving energy under the premise of ensuring the drying effect

4. Market expectation

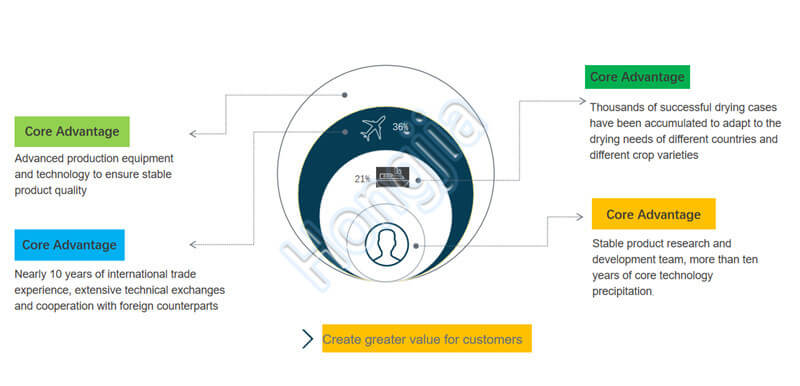

4.1 Competition analysis

(1)Core advantage-advanced production equipment and technology to ensure stable product quality

(2)Thousands of successful drying cases have been accumulated to adapt to the drying needs of different countries and different crop varieties

(3)Nearly 10 years of international trade experience, extensive technical exchanges, and cooperation with foreign counterparts

(4)Stable product research and development team, more than ten years of core technology precipitation.

4.2 Market analysis

(1)Technical research, stable technology research, and development team, more than ten years of drying technology accumulation, active domestic and foreign technical exchanges, and strong technical research capabilities

(2)Market size, the current domestic parboiled rice market is immature and in its infancy stage, the market acceptance is not high, and there are very few people engaged in this research

(3)Eating healthily, the domestic transition from "eat well" to "eat well" to "healthy eating" now makes parboiled rice have a certain market in the future, which will drive the demand for parboiled rice dryers.

(4)In international competition, foreign parboiled rice dryers have been developed for decades, and the products are relatively mature, and they are temporarily at a disadvantage in international market competition.

Hongjia Grain Machinery Co., Ltd. was established in 2000. It is a professional manufacturer and exporter of rice mills, rice processing machines, rice processing plants, rice processing plants, paddy parboiling plants, etc. We can provide a unique overall layout design, customized rice mill products, and installation services for the rice mill production line according to the different needs of customers and site conditions. It combines technology, manufacturing, and sales in one.

Welcome Contact Us!

Hongjia Grain Machinery Co., Ltd

Email: info@ricemillplants.com

Phone/Whatsapp: 0086 13196770111