Why Need to Use the Paddy Rice Cleaning Machine in the Whole Set Rice Mill Plant?

How many kinds of impurities mix inside the paddy?

1. Before the paddy rice is processed, it has to go through multiple processes such as threshing, transportation, purchasing, and storage so that it is inevitable that many impurities will be mixed into it. According to the characteristics of impurities and the characteristics of cleaning, there are mainly five types of impurities in rice: large impurities, medium impurities, small impurities, light impurities, and magnetic impurities.

2. Large impurities: refers to the impurities whose particle size is significantly larger than that of grains and remains on the 5.0mm diameter round-hole sieve;

3. Medium impurities: refer to the impurities that can pass through the diameter of 5.0mm and remain on the sieve with a diameter of 2.0mm. Among them, the tares and the side-by-side stones, and side-by-side mud with similar shapes and sizes are the most difficult to remove.

4. Small impurities refer to impurities whose particle size is significantly smaller than that of grains and can pass through a 2.0mm diameter round hole sieve.

5. Light impurities: refer to impurities with a relatively small relative density.

6. Magnetic impurities: refer to impurities with good magnetic permeability in the magnetic field, such as magnetic metals and their products, magnetic slag.

Why need to use the paddy rice cleaner to clean the paddy rice in the rice mill production line?

1. Protect the rice processing machines in the rice mill plant

The hard impurities in the rice, such as stones, metals, etc., will produce violent friction with the metal surface of the running machine components, which can easily damage the rice processing machines, causing equipment accidents such as rice cleaner destoner machines, rice huller, and even sparks. By removing these impurities, the machine can operate normally.

2. Improve the whole rice mill plant production capacity

Paddy rice contains a lot of bulky and lightweight impurities, such as weeds, rice straws, hemp rope, plastic film, shredded paper, etc. When they enter the rice mill plant processing machines, they will block the feeding mechanism, reduce the feeding amount and make the feeding uneven distribution, thereby reducing the whole production capacity of the rice mill production line. By removing these impurities, the productivity of the whole line can be improved.

3. Protect the environment

There are many small and light impurities such as stucco and dust in the rice. If not cleaned in time, these light and small impurities will cause dust to fly during the processing. Removing these impurities can protect the production environment and protect the health of workers.

4. Improve final white rice quality

If the impurities in the rice are not removed, they will be mixed into the final white rice product, thereby affecting the purity of the product, affecting people's consumption or processing into other foods, and reducing the quality of the product, then finally will influence the whole rice mill plant working purposes.

How many are paddy rice cleaner machines working in the rice mill plant?

The cleaning of paddy is mainly based on the difference in physical properties between impurities and paddy, and there are professional rice cleaner machines for cleaning paddies, such as cylinder pre-cleaner machines, vibrating cleaner machines, and plane rotary cleaner machines.

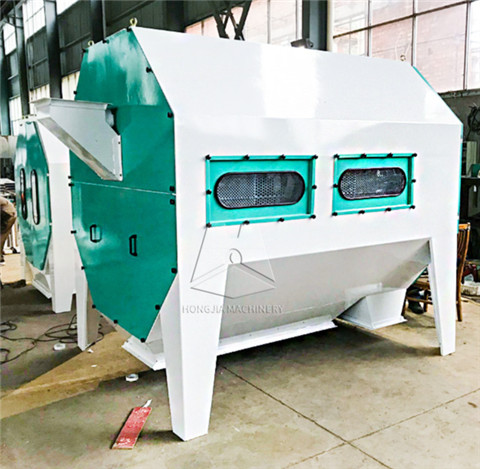

1. Cylinder pre-cleaning machine

The main function of the cylinder pre-cleaner machine is to remove the larger impurities in the rice, such as rice straw, rice ears, mud blocks, packaging materials, etc. Ensure the safety of the subsequent rice milling equipment and prevent the subsequent rice milling production line equipment from being blocked. The structure of the pre-cleaner machine is relatively simple and the operation is convenient, and it is generally used in the first cleaning process of the grain processing production line.

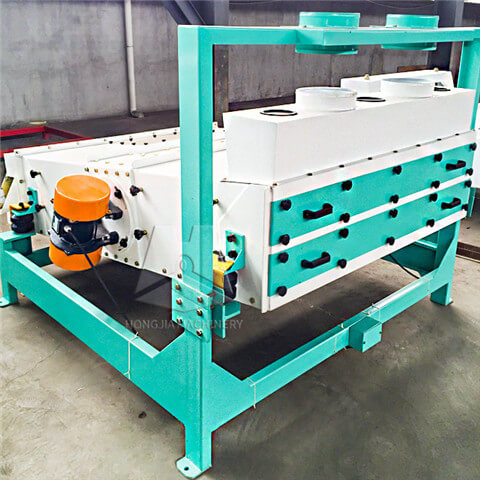

2. Vibrating paddy rice cleaner

Vibrating paddy rice cleaner is a relatively advanced type of screening equipment combined with a windscreen. It is the most widely used cleaning equipment in rice cleanings such as rice mill plants and flour processing production lines. There are two vibration motors as vibration sources. This vibrating screen has a simple structure, easy operation, good screening effect, stable and reliable structure, and good sealing performance. It is the mainstream equipment in screening and grading equipment.

3. Plane rotary paddy rice cleaner

The drying and lifting of the plane rotary rice cleaner machine make a circular motion in the horizontal plane, which is very beneficial to the automatic classification of the line. Therefore, the screening time of the material relative to the screen surface is long, and the chances of contacting the screen holes are more. It works well for cleaning small and medium magazines. Its overall structure is more reasonable, compact, beautiful, and durable, and the installation and adjustment are more convenient.

And besides these mainly used rice cleaner machines, we also have other model cleaner machine capacities and details can be customized according to client's needs.

Hongjia Grain Machinery Co., Ltd. was established in 2000. It is a professional manufacturer and exporter of rice mills, rice processing machines, rice processing plant, rice processing plants, paddy parboiling plant, etc. We can provide a unique overall layout design, customized rice mill products, and installation services for the rice mill production line according to the different needs of customers and site conditions. It combines technology, manufacturing, and sales in one.

If You Are Ready to Start a Rice Milling Business, please contact us for the Rice Milling Machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now!

Welcome Contact Us!

Hongjia Grain Machinery Co., Ltd

Email: info@ricemillplants.com

Phone/Whatsapp: 0086 13196770111