The Causes and Solutions of 13 Problems Frequently Encountered During the Use of Rice Mill Plant

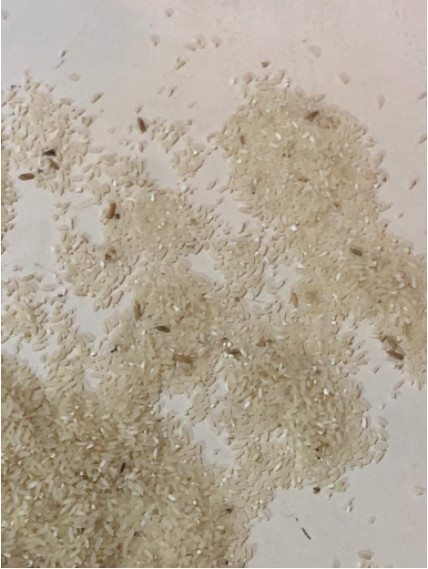

If the final rice has some other color rice, how to solve it?

If the final rice includes some other color rice, it may be is some green paddy can't mill according to the rice mill machine. If you have such a situation, maybe because your rice mill production line is without a rice color sorter, we suggest adding one set color sorter in the rice mill plant. If you did it can solve this problem.

If the destoner can't use it very well in the rice mill plant, how to solve it?

If the paddy is not going to elevator 2 for transfer to husker. it's come out where stones are to come, So paddy is not entering elevator number two. Even if put paddy manually at the end of the destoner but it still reverses back to the stones outlet. This problem has two reasons, one is the electric motor is put opposite, you can install the electric motor for the correction. the second reason is you need to adjust the air hole in the machine. so that it can work very well.

If the rolling bearing fails, how to solve it?

If the rice mill is working for a long time and the bearing is not added with lubricating oil, the temperature will be too high and deform, resulting in abnormal vibrations. Solution: Turn off the equipment, interrupt the power supply, dissipate the bearing, and add it after the temperature drops. Lubricant, if it is deformed, it needs to be replaced in time

How do solve the rotational speed ratio problem?

The drive belt is off-track or the tension is insufficient, and the speed is not up to the standard during rice milling, resulting in a decrease in production efficiency. Solution: Turn off the equipment and power supply, correct the belt and adjust the tension, and replace the belt if necessary

If the grinding roller fails, how to solve it?

The quality of the finished rice largely depends on the grinding roller. It is a consumable item and needs to be replaced regularly to ensure the production effect.

If the rice mill is closed and the output drops, how to solve it?

The main reasons: the feed volume is too large, the discharge port pressure is too large, or the discharge port is too small; the discharge port is blocked by rice bran, which may be caused by slippage of the transmission belt, roller wear, or rice knife wear; raw material moisture is too high or screw head Worn and loose.

If the rice bran contains rice, too much-broken rice, how to solve it?

The main reasons: the rice sieve is damaged or the joint seam is too large; the joint between the conveying head and the emery roller is not flat, and the surface of the emery roller is uneven; the exit of the rice machine is not smooth; the rice knife is too thick, and the distance between the roller and the rice knife is too small; the speed is unstable.

If the current suddenly increases and decreases, how to solve it?

Main reasons: feed inlet broken, pressure door failure, rice sieve damaged, rice sieve bracket broken; foreign matter or feed volume is too large in the machine; outlet pressure door fails, rice sieve is blocked, rice bran is not discharged smoothly; rice tube Or the bran pipe is blocked; the power supply is out of phase.

If the accuracy of the fuselage is reduced, and the roughness is uneven, how to solve it?

The main reason: the rice knife is worn; the feed is too small or the pressure at the discharge port is too small.

If the body vibrates greatly and the bearings are hot, how to solve it?

Main reasons: unbalanced shaft or pulley; loose anchor bolts; excessive or lack of oil in the bearing; excessively dirty lubricating oil.

If there is a strange sound and smell, how to solve it?

The main reasons: the roller is loose or broken; foreign objects fall into the machine; the bearing and seat are damaged; the transmission belt is slipping; the nut is loose.

If the V-belt fell off during the operation, how to solve it?

Reasons:

(1) Improper installation. Due to the unreasonable relative position of the rice mill and the power machine (motor or diesel engine), the axis lines of the two pulleys are not parallel, or the two pulleys are not in the same plane, which causes the V-belt to wear intensified during operation, and the wear of the V-belt is worse. The belt cannot be operated. Remedy: When installing for the first time, set the foundation bolts to the right position; increase the size of the foundation; pay attention to the correct adjustment during installation, the two-wheel axes are parallel, and the two pulleys should be in the same plane; the anchor bolts must be tightened.

(2) The belt is too loose. If the V-belt is inappropriate or is too loose if it is not adjusted in time, the belt will easily fall off during operation. Remedy: Regularly check the fastening anchor bolts; adjust the relative position of the power machine and the rice mill in time to make the V-belt sink in the range of 10-15mm. The anchor bolts should have locking pieces to prevent loosening. But the belt must not be too tight, otherwise, it will increase the wear of the V-belt or the bearing. In addition, the V-belt should be replaced in groups after it is worn out.

Hongjia Grain Machinery Co., Ltd. was established in 2000. It is a professional manufacturer and exporter of rice mills, rice processing machines, rice processing plants, rice processing plants, paddy parboiling plants, etc. We can provide a unique overall layout design, customized rice mill products, and installation services for the rice mill production line according to the different needs of customers and site conditions. It combines technology, manufacturing, and sales in one.

Welcome Contact Us!

Hongjia Grain Machinery Co., Ltd

Email: info@ricemillplants.com

Phone/Whatsapp: 0086 13196770111