How to Use and Maintain the Combined Rice Mill Plants Machine

Many clients will ask how to use and maintain the rice mill machinery before ordering or after getting the machines. Today let us talk about something that needs to be noticed especially.

Combined Rice Milling Machine Structure

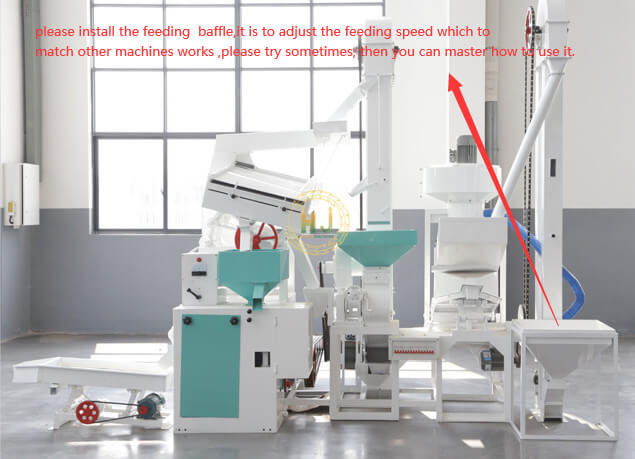

The combined rice milling machine consists of elevators, paddy destoner cleaner, rice huller, paddy rice separator, rice whitener, and broken rice screen. which are connected by elevators, working automatically. It can labor and energy, increasing working efficiency greatly.

Something needs to be noted during using:

1) Paddy destoner cleaner is used to remove the stone and impurities from raw paddy. But some clients will meet the problem of stone outlet will discharge the paddy. This is because the air door on the pipe does not adjust well. Or the draught fan motor is connected in reverse. After adjusting well, the machine will work well.

2) The rice huller is the machine to remove the husk from the paddy and get brown rice. Its hulling rate can reach 85-90%, if, with the high broken rate or low hulling rate, The rubber roller is either too tight or too loose, need to adjust the rubber rollers' space correspondingly.

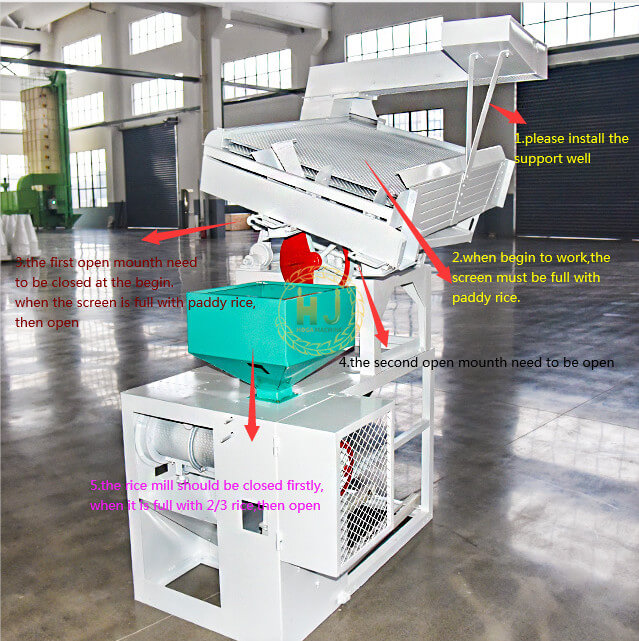

3) The Paddy rice separator, working will affect the following machines working. So it is a key part of rice processing plants. The separator screen must be full. It has 2 outlets. The upper one and the below one. The upper one should be closed until the screen is full of paddy, then open (brown rice to whitener machine). The below outlet is open all the way (raw paddy to rice huller again)

4) rice whitener is to make brown rice white. To reduce the broken rate and milling time, firstly the machine should be closed. Until it is full with around 2/3 brown rice, then open the machine. Also can adjust the pressure mold to control the broken rate and whitening degree.

5) Elevator, we need to notice the first one, feeding the paddy at a uniform speed to avoid its block.

We must observe every step to ensure that each step is skillfully operated to achieve continuous operation of the whole rice mill plant machine

How to maintain each machine in rice processing plants

After learning how to use the rice mill machinery, then also need to know how to maintain the machines to guarantee their long-time service.

1) Paddy destoner cleaner: The screen should be inspected and cleaned every shift to prevent clogging of the screen holes. The screen should be replaced timely if damaged. Also, need to clean the grains and fine sand in the hood regularly.

2) rice huller: When the fast roller rubber layer is worn to about half, the fast and slow rollers can be used interchangeably. When the rubber layer of the rubber roller wears out and the iron core is exposed, new rubber rollers should be replaced. The two rollers should be replaced at the same time, and the surface of the rubber roller should be kept flat.

3) Paddy rice separator: Check the lubrication condition of the transmission part, and add lubricating oil (grease) in time.

4) rice whitener: The chaff suction fan impeller and air duct should be cleaned once every two months.

5)Common maintenance of each machine:

1. Maintain one time every 3 months and overhaul one time a year.

2. Lubricating oil should be added to each transmission part regularly.

3. The bearing is generally replaced with grease one time every 6 months.

4. Where the bearing is overheated, the grease is hardened, the oil color becomes dark, or the oil surface has water droplets and dirt, replace the grease immediately.

When finding the machine vibrates violently, shut down the machine immediately for an inspection.

We Hongjia Grain Machinery Co, Ltd are more professional in rice mill plant manufacturing with rich experience. Our rice mill machinery has been exported to many countries such as Nigeria, Ghana, Tanzania, Zambia, Malawi, Benin, Kenya, Togo, Burkina Faso, Mozambique, Senegal, Côte d'Ivoire, Uganda, Cambodia, Indonesia, Philippines, Peru, Mexico, etc. With high quality, all get good feedback from clients, even some clients will meet some small problems during installation or use, but under our guidance, they solve it soon. Also satisfied with our after-sale service. So no worries about cooperating with us. we guarantee you quality, timely delivery, and after-sale service.

Our services are as follows:

1) According to the client's requirements, we recommend suitable machines and spare parts

2) After talking well with a client, we can design the complete project including the rice milling processing flow and layout

3) Good machine manufacturing and timely machine delivery after the order

4) Arrange engineers for installation and guide and train clients on how to use and maintain the machine

5) Good after-sale service,one-line video for guiding

Hongjia Grain Machinery Co. Ltd. was established in 2010, in China. The factory covers an area of 50 acres and has a plant area of 30,000 square meters. 110 employees. It is a backbone enterprise integrating the research, development, production, and sales of grain processing equipment, the main products are a paddy cleaning machine, rice Destoning Machine, grader for rice milling, rice grain dryer, Paddy Separator, super dust deputy cyclone, bucket conveyor and complete sets of rice milling equipment with daily output of 15 ton-500 ton series.

if you are looking for a real bucket conveyor manufacturer, or if you are still hesitating about where to buy a grain elevator, please contact us quickly for details.

Welcome, Contact Us!

Hongjia Grain Machinery Co., Ltd

Email: info@ricemillplants.com

Phone/Whatsapp: 0086 13196770111