What is the Application of Rice Mill Polisher in the Rice Mill Process

Are you looking for a rice polisher?

Do you want to know what is rice polishing?

Do you want to know the application of rice polishing machines?

......

This article can solve all your problems.

What Is Rice Polishing?

Rice polishing is an indispensable process for producing high-quality refined rice in rice mill plant. The polishing treatment can not only remove the floating bran on the surface of the rice grains but also play the role of pre-gelatinization and gelatinization of the starch on the surface of the rice grains.

The degree of starch gelatinization and gelatinization on the surface of rice grains depends entirely on the effect of water and heat or the addition of edible throwing aids during the rice polishing process. Polishers that can produce hydrothermal effects can achieve good polishing results. It is a very important piece of equipment in rice mill plants.

The Principle of Rice Polishing Machine

Treating the surface of the rice grains can make the rice grains crystal clear and transparent, and form a very thin gel film on the surface of the rice grains. This process is called rice polishing. The main function of the rice polishing machine is to remove the bran powder adhering to the surface of the white rice. After the surface of the rice is polished, there is a protective layer of wax, which can not only prevent the rice bran from sticking or falling off in the production, storage, transportation, and sales links, ensure the cleanness of the rice, but also improve the quality and commodity value of the finished rice, Is conducive to the storage of rice, maintains the freshness of rice, and improves the edible quality of rice.

Working Process of Rice Polishing Machine

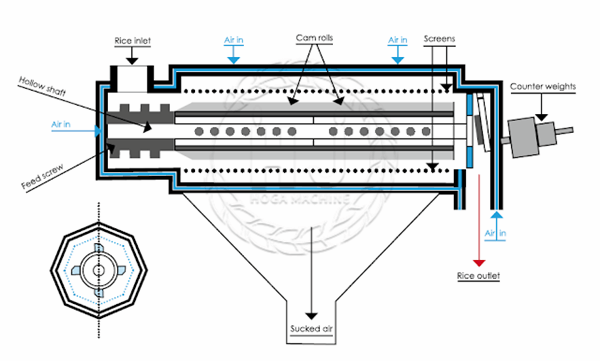

The white rice milled by the rice mill to the standard one-meter accuracy flows down from the feed port into the polishing room, and at the same time, the heated water (used when the room temperature is lower than 15°C) is passed through the flow meter through the rubber tube through the temperature-controlled water tank. The air-water mixing nozzle forms water mist through high-pressure air and enters the hollow main shaft impingement area.

Under the action of strong negative pressure suction, the water mist passes through the main shaft and the vent holes of the polishing roller and enters the surface of the polishing roller to mix with rice and adhere to it. On the surface of the rice grain, the surface of the rice grain is moistened and softened. Through the rotating movement of the polishing roller in the polishing chamber, the rice grains are continuously moved in the polishing chamber.

During the movement, relative movement, relative friction and squeezing occur between the rice grains, between the rice grains and the polishing roller, and between the rice grains and the rice sieve. Because the surface of the rice grains is wet and soft, this friction will remove the bran powder and acne on the surface of the rice grains on the one hand. On the other hand, the starch layer on the surface of white rice undergoes gelatinization and crystallization during the friction extrusion process to form a bright protective film, which improves the surface finish and prolongs the storage time of the later rice. The fine rice bran and fine chips produced during the polishing process are removed from the machine through the rice sieve under the action of negative pressure and strong suction.

Characteristics of Rice Polishing Machine

1. The surface of the rice is polished by the automatic water-adding constant temperature device and the multi-position spray device is smooth and translucent. Greatly increase the commodity value of rice. To

2. Novel design, beautiful appearance, convenient operation, stable and reliable mechanical performance. To

3. According to the shape, length, moisture, and quality of rice, stabilize different polishing schemes and improve the professional performance of the polishing machine. To

4. Improve the commercial value of rice and extend its shelf life of rice.

5. The built-in single-roller polishing machine has the characteristics of a small footprint and convenient installation and operation.

Main Structural Features and Functions of Rice Polishing Machine:

The main structures of various types of rice polishing machines are similar. They are mainly composed of a spraying part, a polishing part, a water supply system, and a blower mechanism. The feeding device and the discharging device are also important devices for various types of rice polishing machines.

1. Spraying Water Part

The spraying water part is composed of the nozzle, nozzle cleaner, water mixer, feeding screw, stirring roller, and so on. When the material passes through the flow meter, the flow rate is measured, thereby controlling the amount of water added.

2. Polishing Part

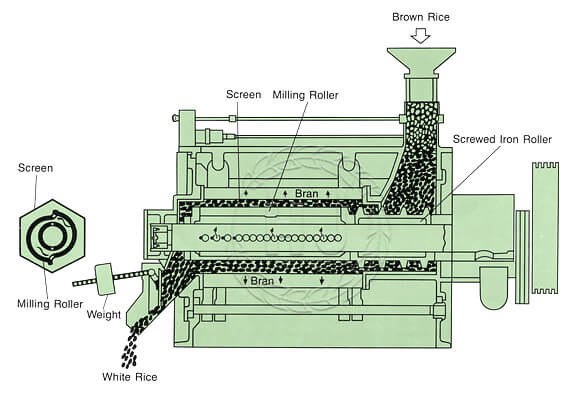

The polishing part is the core part of the rice polishing machine. It is composed of a feeding screw, a polishing roller, an octagonal sieve tube composed of eight rice sieves, and a discharge pressure gate. The polishing roller is divided into iron roller and sand roller according to the material properties.

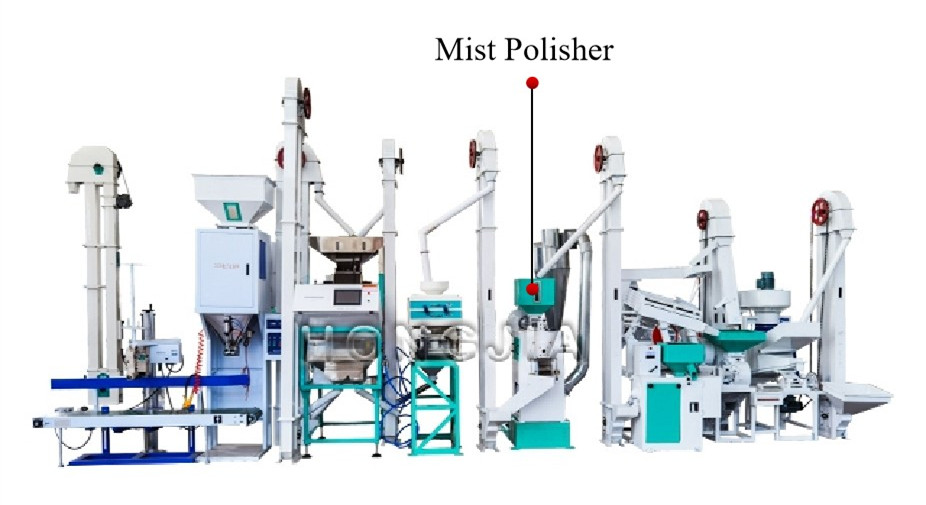

Hongjia Grain Machinery Co., Ltd. was established in 2000. It is a professional manufacturer and exporter of rice mills, rice processing machines, rice processing plants, rice processing plants, paddy parboiling plants, etc. We can provide a unique overall layout design, customized rice mill products, and installation services for the rice mill production line according to the different needs of customers and site conditions. It combines technology, manufacturing, and sales in one.

If You Are Ready to Start a Rice Milling Business, please contact us for the Rice Milling Machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now!

Welcome Contact Us!

Hongjia Grain Machinery Co., Ltd

Email: info@ricemillplants.com

Phone/Whatsapp: 0086 13196770111