What is a Color Sorter Machine?

Color Sorter Introduction:

The rice color sorter is a device that uses light detection technology to automatically sort out the heterochromatic particles in the granular material according to the difference in the optical characteristics of the material. At present, the rice sorter is used in the fields of bulk materials or packaging industrial products, food quality inspection, and grading.

Color Sorter Structure

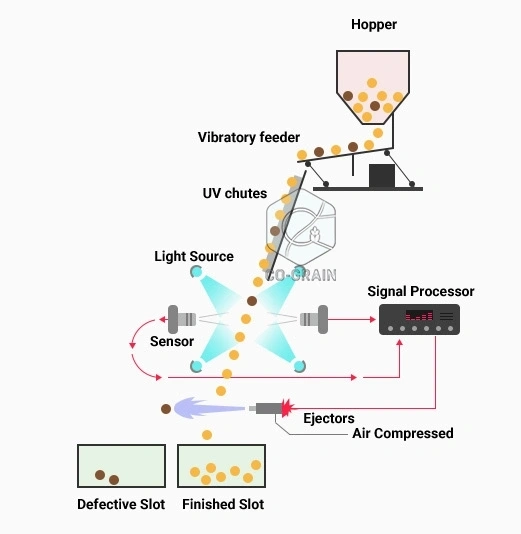

The color sorter machine mainly consists of four systems and a man-machine interface

1. Feeding system (feeding hopper, vibrator, chute)

2. Detection system (Led lamp, camera, etc.)

3. Signal processing system (drive board, PC motherboard, etc.)

4. Separation system (injection system, hopper)

5. Human Machine Interface (GUI)

Color Sorter Working Principle

1. The rice color sorter machine is mainly composed of a feeding system, optical detection system, signal processing system, and separation execution system

2. The main technical indicators of the color sorter

1) Output processing: Output is the number of materials that can be processed per hour. The main factors affecting output are the vibration amplitude of the vibrator, the length of the chute, and the purity of the raw materials. At the feeding end of the trough, increase the processing capacity; otherwise, it is necessary to reduce the vibration amplitude of the vibrator.

2) Color sorting accuracy: Color sorting accuracy refers to the percentage of impurities selected from the raw materials of the total impurities contained. The color sorting accuracy is mainly related to the movement speed of the material and the purity of the raw material. The shorter the chute, the slower the movement speed. , Leaving enough time for the processing system to remove impurities and improve the accuracy of color selection.

3) Take-out ratio: The take-out ratio refers to the ratio of the number of impurities in the waste selected by the rice sorter to the number of normal materials. The level of the take-out ratio can be adjusted, and the adjustment of the take-out ratio is mainly achieved by adjusting the energization time of the solenoid valve.

Scope of Application of the Color Sorter Machine

1) Agriculture

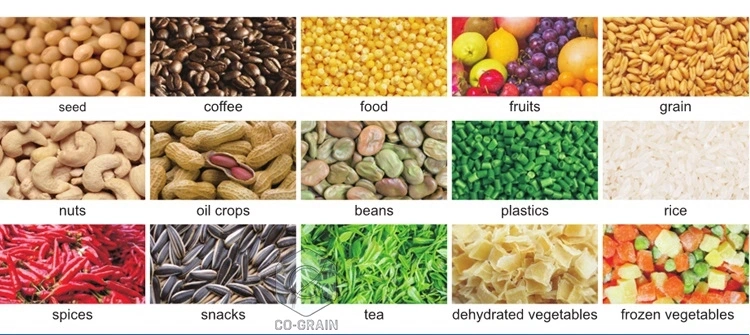

The appearance of the color sorter machine was first applied to agriculture. It can also be said that the rice color sorter machine was born for agriculture. The main color sorting materials include rice, miscellaneous grains, tea, beans, nuts, seeds, medicinal materials, seafood, etc., including a rice sorting machine, miscellaneous grains sorting machine, tea sorting machine, soybeans Color sorter, etc., one machine for multiple purposes.

2) Industry

Garbage classification and recycling are becoming more and more popular. Many businesses have created business opportunities from garbage and started to use it in plastics, minerals, plastic particles, and other industries.

3) Handicraft market

Later, people discovered that as long as there is a difference in color, the rice color sorter can pick it out, like Buddhist beads, jewelry, etc.

4) Flowers

The petals have distinct colors, which can be picked out by the color sorter

Installation Instructions for Color Sorter

Installation environment requirements

1) Please install this rice sorter on a level and fixed non-vibration platform or level ground, and check the level of the machine. The level of the machine can be adjusted with a level<=2/1000mm

2) Please do not install this equipment in low-temperature, high-temperature, humid, or dusty places. Try to keep the ambient temperature of the color sorter within the range of 0-40 degrees.

3) Please avoid installing in an environment with strong electromagnetic interference, such as electric welding, high-frequency emission, etc.

4) Please avoid installing in a place where there is direct sunlight and strong light from the lighting lamp. Please do not directly weld the device. If you want to weld, please cover the body with canvas, etc.

Common Problems of the Color Sorter: Does Not Work Well

1) The sensitivity adjustment is too low. Please adjust the sensitivity

2) Check whether the gas valve is normal. If the gas valve is abnormal,

3) There is too much dust on the glass of the sorting room. Please clean it up

4) The LED does not light up

5) Timing parameter setting is wrong, please reset

6) The rice road jumps to the rice. Please clear the rice road

7) Observe whether the nozzle is aligned with the metering channel

8) The raw material contains large impurities, and the flow rate of the vibrator is large. Please adjust the appropriate sensitivity and flow rate

Clean Regularly

Keep the rice color sorter clean to maintain hygiene and efficiency standards. The sorting rate will gradually decrease as the machine becomes dirty, and unclean machines are more prone to failure than clean machines.

The rice sorter is equipped with an air gun, which can be used to remove dust and debris from the machine.

Do not use steel wool, scraper, or abrasives on any parts of this machine, and do not damage the vibrator tray, feeding chute, optical window, or special surface of the control panel

Henan Co-Grain Machinery Engineering Co., Ltd. was established in 2000 in China. The factory covers an area of 50 acres and has a plant area of 30,000 square meters. 110 employees. It is a backbone enterprise integrating the research, development, production, and sales of grain processing equipment, the main product is a paddy cleaning machine, rice Destoning Machine, grader for rice milling, rice grain dryer, Paddy Separator, super dust deputy cyclone, bucket conveyor and complete sets of rice milling equipment with daily output of 15 ton-500 ton series.

If you are looking for a real bucket conveyor manufacturer, or if you are still hesitating about where to buy a grain elevator, please contact us quickly for details.

Welcome, Contact Us!

Henan Co-Grain Machinery Engineering Co., Ltd.

Email: info@ricemillplants.com

Phone/Whatsapp: 0086-18339828199